Sponsored Blog Post by: Metropolitan Ceramics

Flooring specifiers have choices when it comes to selecting products for challenging commercial environments. Quarry tile, however, is the superior choice when durability and performance are critical, and new quarry tile offerings from Metropolitan Ceramics offer superior functionality plus updated style.

New Choices in Quarry Tile, Immediate Availability

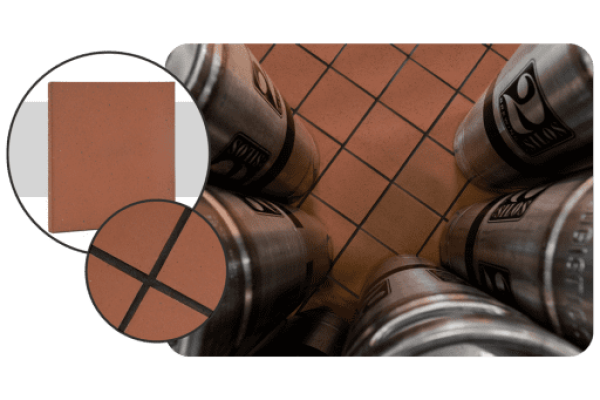

The leader in high-quality quarry tile, Metropolitan Ceramics recently added the new QuarryBasics® Ironspot line to its quarry tile offerings. QuarryBasics® Ironspot is a durable matte finish floor tile with a subtle through-body salt and pepper look. Designed with a focus on heavy use, functionality and visual appeal in mind, QuarryBasics® Ironspot stands out as the preferred choice for demanding projects.

Ironspot 6’’ x 6’’ tiles are available in two popular colors, Puritan Gray and Mayflower Red, each with a ½-inch thickness for added strength and performance. In testing, QuarryBasics® Ironspot excelled in eight rigorous durability categories, including breaking strength and abrasion resistance.

For decades, customers have trusted Metropolitan Ceramics’ supply chain. While other quarry tile manufacturers are struggling to meet demand, our manufacturing facility is running at capacity, ensuring immediate availability for QuarryBasics® Ironspot and Metropolitans’ other quarry tile lines.

What is Quarry Tile?

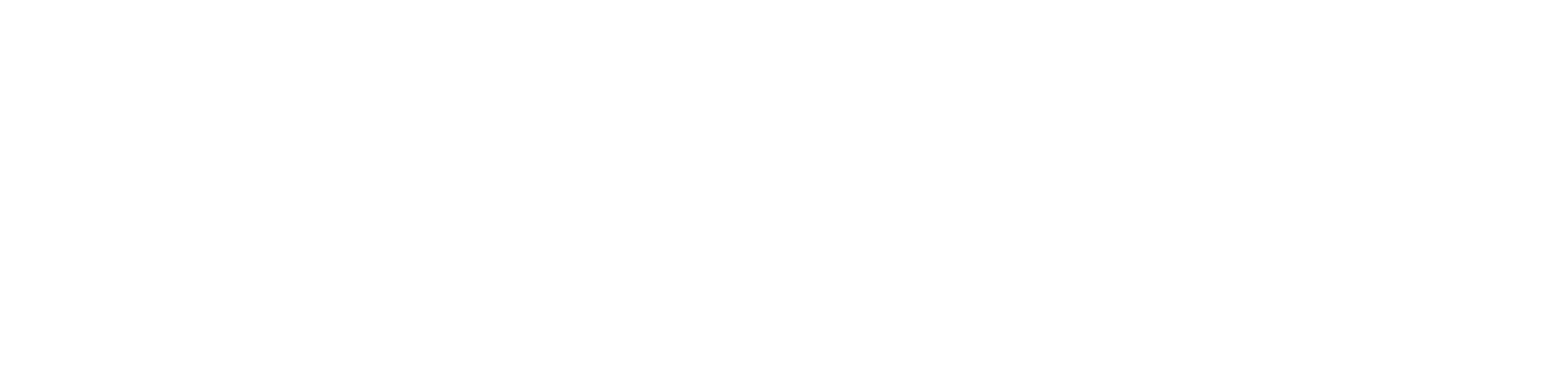

An unglazed product, quarry tile is valued for its durable and vitreous nature as well as its natural slip resistance. Time and again, designers and other specifiers choose this vanguard in commercial flooring for harsh environments.

While many tile manufacturers use presses to produce stamped quarry tiles, the highest quality tiles are manufactured using an extrusion process similar to brick-making. As it does for bricks, extrusion creates a highly tight, dense, and vitreous tile body, surpassing other manufacturing methods. The strength of quarry tile also comes in its firing process. Once dried, quarry tiles are fired at temperatures exceeding 2,000 degrees Fahrenheit, making them highly resistant to moisture.

Not Just for Kitchens

While commercial kitchens are the most common application for quarry tile, it is also ideal for:

- Restaurant and cafeteria dining rooms

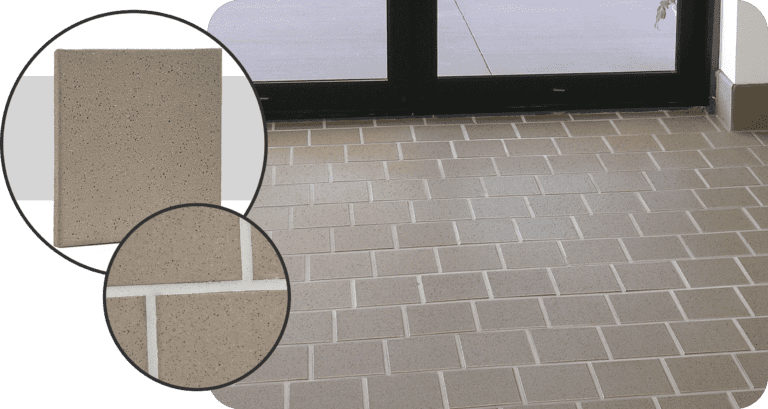

- Entryways and lobbies

- Auto dealerships

- Retail

- Convenience stores

- Gas stations

- Public restrooms

- Patios, courtyards, plazas

- Pathways and walkways

The Metropolitan Ceramics Difference

Metropolitan Ceramics is part of Ironrock, a fifth-generation, family-owned company with more than 150 years of experience in brick and tile manufacturing. A testament to its consistency and reliability, millions of square feet of Metropolitan Ceramics quarry tile have been installed throughout the United States.

Metropolitan Ceramics manufactures its tile through an extrusion process for lasting performance. As a result, it outperforms pressed tile options when it comes to strength, durability, and resistance to moisture and stains. The extrusion process also produces a ribbed back for superior mortar adhesion. Metropolitan quarry tiles offer a long lifespan for long-term cost savings.

Balancing durability and aesthetics, Metropolitan Ceramics’ five lines of quarry tile, including our exciting new QuarryBasics® Ironspot, are the high-performing, attractive option for demanding commercial projects. Reach out to Metropolitan Ceramics for more information.